Paint Shop

Our company has a modern technological base that enables us to provide both powder coating and wet painting services.The choice of technology is always adapted to the project’s characteristics and our clients’ specific requirements.

For each method, we ensure comprehensive surface preparation (pre-treatment), ensuring strong paint adhesion, effective corrosion resistance, and high durability.

Powder Coating

Our automatic powder coating line is a modern solution that ensures the highest quality, repeatability, and durability of powder coatings. The coating process is fully automated, including surface preparation, powder application, and oven curing.

The line consists of three main workstations:

- Surface preparation station:

(L × W × H) = 4 m × 1.5 m × 2 m - Powder application station with electrostatic guns:

(W × H) = 1.2 m × 2 m - Curing station:

(L × W × H) = 8.4 m × 1.5 m × 2.1 m

All stations are connected by a guide rail system that ensures smooth and continuous product flow between each stage of the process. This setup provides high efficiency, minimal risk of part damage, and complete repeatability and quality of the applied coatings.

Surface Preparation Station

Powder Application Station

with electrostatic spray guns

Curing Station

Wet Painting

The wet painting process begins with thorough surface preparation, which is crucial for achieving a durable and aesthetically pleasing coating.

Painting is then carried out manually by experienced painters using high-quality paints and modern spray gun systems.

After paint application, the parts are cured under controlled temperature conditions, ensuring optimal mechanical properties, high wear resistance, and excellent coating adhesion.

This technology makes it possible to achieve high-quality coatings with precise coverage, even on components with complex shapes.

Quality Assessment of the Painting Process

Our company places great importance on the quality and repeatability of the painting process. Every stage – from surface preparation and application parameter control to final coating evaluation – is subject to strict inspection procedures.

Quality control includes measurement of coating thickness, assessment of adhesion, gloss, color, and mechanical resistance, all in accordance with international ISO standards.

Our coating testing includes:

- Cross-cut test (ISO 2409) – evaluation of coating adhesion

- Coating thickness measurement (ISO 2808)

- Pencil hardness test (ISO 15184)

At the client’s request, we can also carry out additional tests required by technical specifications. All measurements are documented in inspection reports, ensuring full traceability and transparency of the process.

We work with renowned industrial paint suppliers, allowing us to use proven, high-quality coating systems. Access to modern mixing facilities and advanced coloring technologies enables us to achieve virtually any paint color, in accordance with RAL palettes. Our individual approach allows us to select the type of paint, color, and gloss level appropriate to the nature of each project – both for powder coating and wet painting.

Through advanced measurement methods and process data analysis, we ensure high durability, aesthetic quality, and full compliance of coatings with technical requirements. Continuous quality assessment allows us not only to eliminate potential nonconformities but also to constantly improve our technologies and raise the standards of our services.

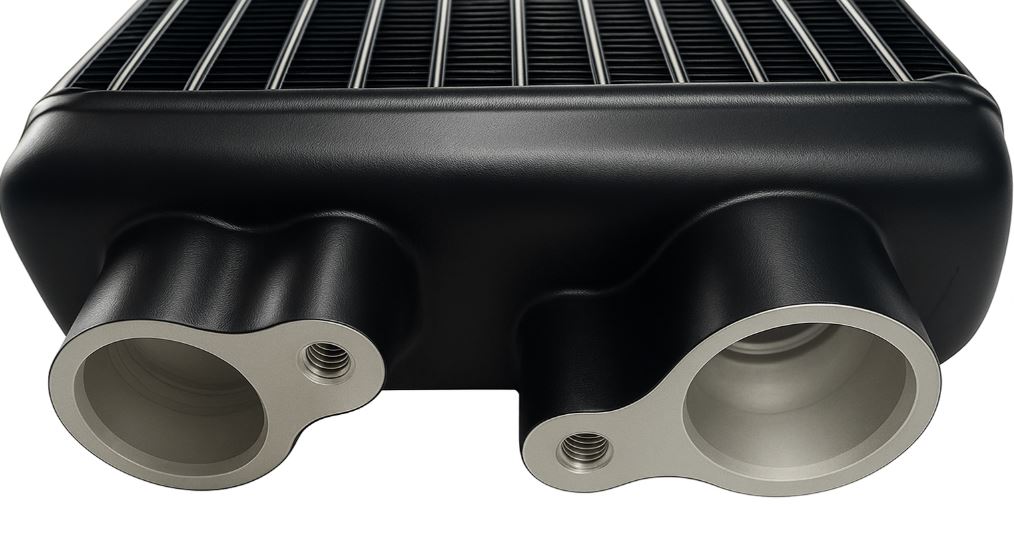

Examples of Our Work